5 Corrugated Solutions for Greener Box Production

Corrugated packaging is widely considered the more sustainable option when compared to plastic materials, but does this advantage also extend to the production environment? As members of the box making industry, it is our responsibility to evolve our equipment, products, and practices to be more eco-conscious.

Packaging manufacturers are facing increased pressure to meet local initiatives and regulations, such as California’s SB 54 and growing Extended Producer Responsibility (EPR) measures. To assist box makers in their journey to more sustainable practices, we have created the Greene Certificate program, which recognizes GHG partner solutions that improve material recyclability, reduce waste and pollution, and optimize energy efficiency.

The NEW Greene Certificate Program

Greene House Group is proud to represent manufacturers that prioritize green production practices and innovate products that can help west coast operations in their sustainability initiatives. The Greene Certificate program highlights partner solutions that:

Save energy and noise pollution with more efficient components, low power modes, LED lighting and more, prioritizing sustainable energy and energy efficiency.

Reduce substrate, ink, and water waste, which is better for your business, and better for the planet.

Decrease material consumption with solutions that make it easier to track usage and view trends to help reduce material usage and waste.

Make smarter choices with your raw materials, storage, and logistics can reduce costs and your overall impact on the planet.

5 Greene Certified Solutions for Eco-Conscious Production

This innovative load former is fully electric and doesn’t require pits, pneumatics, or hydraulics. The system can be placed on “eco-mode” for minimal energy consumption and requires no air, oil or gas to run, conserving natural resources.

This eBreak bundle breaker is also fully electric with no pits, pneumatics or hydraulics. It boasts the same green benefits as the eZF load former with a low-power eco-mode and no natural resource requirements. With clean breaks on a variety of box configurations, the system also helps reduce board waste from messy breaks and customer rejections.

The InKomand control system maintains optimal ink performance with precise temperature control during print runs. Ink temperatures outside the range of 66-74°F can cause dramatic swings in pH and viscosity, leading to incredible substrate waste, increased set up times and an overall inability to print.

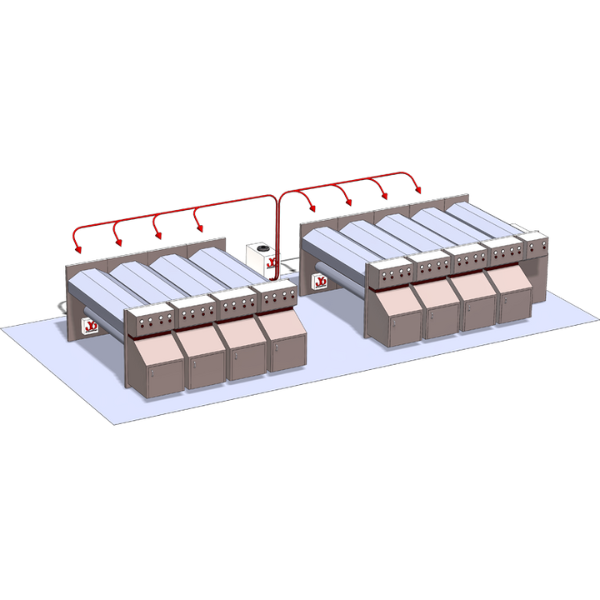

This automated drying system is available as an upgrade to the ColorDry® XL3000 IR drying systems and dramatically reduces energy consumption. The system automatically optimizes drying temperatures according to the specific needs of each job. Just set it and save!

5. InkSave Wash Up Management System

This ink management system is designed to extract the maximum amount of ink in the chamber or drop pan before wash-up, which is shown to reduce your ink loss by up to 80% and water consumption by up to 50%. Ink is a precious resource in printing, with special chemical disposal requirements; save your resources while saving the environment with InkSave.

Your West Coast Partner to Corrugated Solutions

Greene House Group has been serving western USA boxmakers with tailored, goal-driven solutions for over 20 years. We live in California, we know the industry and we understand the unique nuances of the western boxmaking market. We look forward to expanding our list of Greene Certified products as the industry moves more towards full sustainability, with the West Coast leading the way. To learn more about our solutions and how they can assist your own operations, contact Frank or Hayden at Greene House Group today!